Due to the increase in the variety of products of various enterprises, the replacement of molds in production has become very frequent. Now some injection molding factories switch between two products for half an hour to an hour, and even more, two or three hours, like this. The injection molding factory obviously cannot adapt to the current production requirements of “multi-variety, small batch”. So how can we get to the current rhythm?

The answer is to introduce the rapid changeover system of the injection molding machine. The introduction of the rapid mold change system of the injection molding machine can save more than 90% of the mold replacement time. The rapid mold change of Shangchuan can help you to quickly change the mold for 3 minutes, reduce equipment idle time, improve production efficiency and improve enterprise competitiveness.

The rapid mold change system of the injection molding machine is not only considered in the design of the equipment structure, but also in the structural design and standardization of the mold, and the operation on the machine is placed under the machine as much as possible. It completely solves the problem of frequent mold replacement, shortens downtime and improves work efficiency.

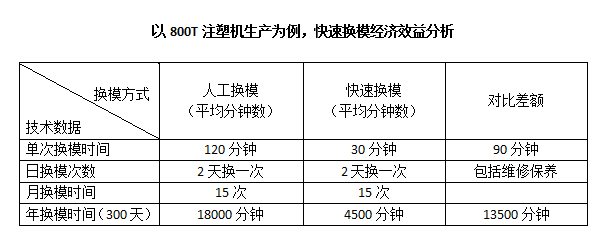

Economic Benefit Analysis of Injection Molding Quick Change After Putting into Use

1. Machine production increases costs

If the production time of the product is 1 minute/PCS, the fast calculation can save 13500 minutes by using the rapid changeover model, and more than 13,500 products can be produced. If the profit of the product is 6 yuan/PCS, the profit will be generated in one year: 13500 pieces × 6 Yuan = 81,000 yuan.

2, Labor costs

Using the rapid changeover system of the injection molding machine, the labor cost is also reduced accordingly. One machine can save labor costs of 15,000 yuan (60,000 * 1/4 manpower) in one year, and one-button mold change can be easily operated by a mold changer.

3. Electricity fee

The temperature difference of the injection nozzle is saved by 90 minutes. The electricity cost is expected to be 20 yuan per day* 5 times for the mold change* The total cost for the 300 days of work per year is 3,000 yuan.

4, Plus the usual enough to buy the pressure plate, screws, wrench tool costs, injection molding machine head repair costs, occasionally artificial pressure plate is not pressed the mold sinking damage heating ring and re-mold adjustment time cost is estimated to be about 6000 yuan.

Other non-benefit benefits

1. Hydraulic clamping replaces manual compression, eliminating the safety hazard of standing at high working position and slipping oil under the foot, increasing production safety;

2. The mold pressing torque is the same and the synchronization ensures the precision and stability of the mold and the injection molding machine, preventing the mold from sinking and the damage of the heating ring;

3. There is no need for wrenches, screws, pressure plates and afterburner accessories to reduce the cost of control and control;

4, Greatly improved the injection rate of the injection molding machine, the annual output value of each machine is significantly improved, and the repair and maintenance is quick and easy, greatly improving the efficiency of the whole mold change, reducing the machine parking, to be replaced.