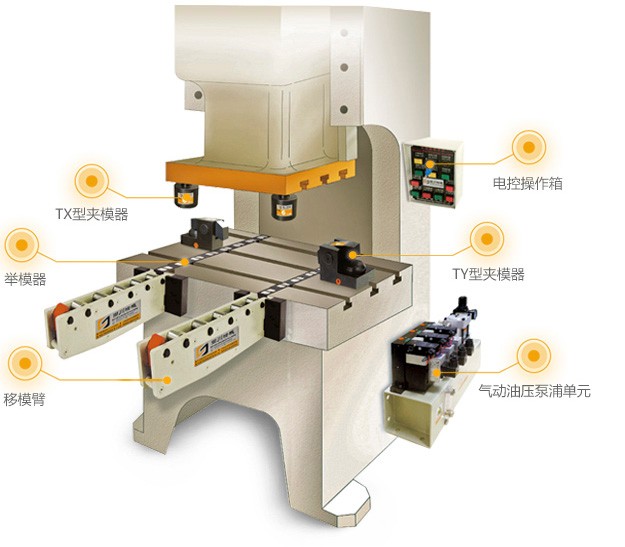

It is an era for making high frequency die change with multiple patterns and small quantity. Quick die change system save time for the die change and ensure the safety of the operation,then raise the competition capability of enterprises.

1.Before operation

Before using this system’s clamps,fist confirm thatthe upper and lower thickness of the die base are within the safe operating limits for the machine(if it is too thick, the clamp can not be clamped ,if it is too thin the die will not be held tightly).

2.During operation

a.Before loosening the clamp,lower the press to bottom base line at the position of six o’clock (when the plate register ‘die’).

b.Before clamping the die ,check to make sure that the die clamp is in the proper position.

c.Before operating the press,the “confirm die change”switch should be at off

(Please pay special attention to this point).

3.During die clamping

a.Before operating the press,check & set the upper and lower clamp to confirm that the die is firmly clamped.

b.Ensurethat hydraulic pressure is enough and there are no leakage.

c.Is air pressure sufficient?(At least 5kg/cm2)

Note:when the system is not being used for a period (two hours or longer),the up/down switch of die clamps should be set at ‘clamp’ to prevent overheating of the magnetic valve.